News and Blog

Paper Made from Sewage

A new Israeli invention is making it possible to produce “scentless paper” – from drain water.

Dr. Refael Aharon of Applied CleanTech has developed a system capable of turning stinking sewage into a renewable and profitable source of energy.

About 99.9% of the drainage which comes out of our homes and flows through pipes is water. The remaining 10% are comprised of solid substances which can be used for the production of cellulose, which is used to produce paper.

These substances include food leftovers, used toilet paper and fiber from clothes which flow into the sewage with the laundry water.So far, these solid substances have been a difficult and expensive nuisance. The process of cleaning the large amounts of processed waste remaining after the wastewater filtration require a lot of money, which pushes up our water tariffs.

Aharon says the process he developed reduces half of the solid substances in the sewage. As a result, the factory needs less electricity and chemicals to purify water – and the money saved may eventually reduce our water bills.

So how does one turn drain water into paper? After the solid substances are filtered and separated from the wastewater, they undergo a drying and purification process to remove bacteria.

The remaining substance, which includes large amounts of cellulose, can be sold to paper manufacturers. Thanks to the system, which has already been installed in one of the sewage purification facilities in southern Israel, paper has already been produced at much lower costs than regular recycled paper.

Aharon had business cards created from the "sewage paper". He says it is possible to produce paper at the size and thickness required for any purpose. "There's no reason not to recycle sewage substances, just like we recycle plastic."

Green Infrastructure

One of the problems in many cities is when it rains very heavily. The rain is too much for the storm sewers to handle and it often ends up causing sewage treatment plants to overflow into the rivers and oceans.

Seattle has had this problem for a long time and is now doing something about it.

Here is the link to the original article: Green infrastructure puts Seattle on the map >

Bill Gates and the Reinvent the Toilet Challenge

Bill Gates through his Gates foundation sponsored a challenge to reinvent the toilet.

Poor sanitation (contact with feces) is the number one killer of children in the world. Four out of ten people in the world have no toilet and that means approximately 2.5 billion people. The toilet as we know it has serious limitations.

The Gates toilet focus started just about a year ago, and including grants announced Tuesday, $370 million in foundation dollars have been committed to reinventing the toilet.

To pass the foundation’s threshold for the world’s next toilet, it must operate without running water, electricity or a septic system, not discharge pollutants, preferably capture energy or other resources, and operate at a cost of 5 cents a day.

Read more at the Business Insider>

Read more at the Gates Foundation >

Dog and Human Waste into Ash

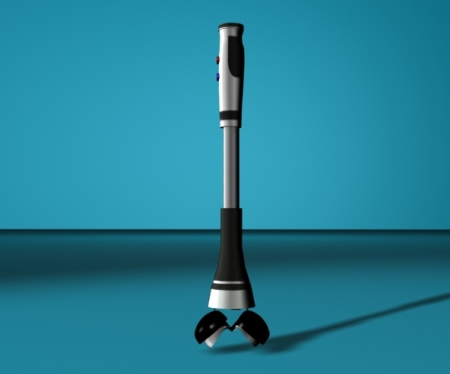

A device designed to scoop and turn dog poop into ash in one minute is getting serious consideration from the Gates Foundation.

The company, Paulee Cleantech, has created a device that scoops up dog poop and then in the chamber adds chemicals transforming the poop.

The toilet, invented by Hebrew University biotech innovator Prof. Oded Shoseyov, decomposes feces and urine using chemicals, which are released upon the pressing of a button powered by a battery or solar cell.

The waste is then chemically broken down and turned into compost, which can be used for farming or other purposes, Hibel said.

Here is the link to the Ashpoopie Website >

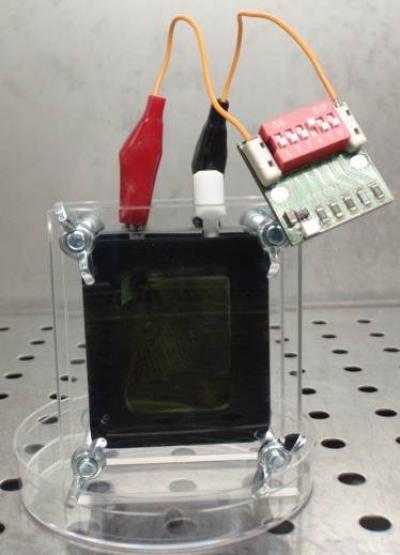

Microbial Fuel Cells

A by-product of biofuel manufacture can power microbial fuel cells to generate electricity cheaply and efficiently, according to scientists presenting their work at the Society for General Microbiology's Autumn Conference. The work could help develop self-powered devices that would depollute waste water and be used to survey weather in extreme environments.

Distillers Dried Grain with Solubles (DDGS) is a waste product from bioethanol production that is commonly used as a low-cost animal feed. Researchers from the University of Surrey incorporated DDGS together with bacteria-inoculated sludge from a waste water treatment plant in their microbial fuel cell.

The design of the fuel cell meant that the bacteria, which used the DDGS for growth, were physically separated from their oxygen supply. This meant that the bacteria were forced into sending electrons around a circuit leading to a supply of oxygen. By tapping into this electron flow, electricity could be generated from the waste.

Here is the link to the article in Phys Org >